Rhebo Industrial Protector

Industrial network monitoring with real-time anomaly detection

Rhebo Industrial Protector for industrial control systems (ICS) for Industry 4.0

Contemporary industry systems are characterized by increasing complexity and connections to networks outside of the industrial setting (i.e. internet). The key to efficient and safe production lies in the effective management of the ICS and the maintenance of a high network quality. Only those who guarantee digital transparency can protect their production from technical disruptions, network errors and advanced cyber threats. Rhebo Industrial Protector supports you in the effective control, optimization and protection of complex ICS in accordance with industry standards such as IEC 62443 and ISO 27001.

The connection to internet services, remote access points and the lack of security due to the design of industrial components increase the risk of malfunctions, manipulation via remote access, cyber attacks and technical errors in the ICS. The industrial network monitoring system Rhebo Industrial Protector monitors all communication within an industrial control system (ICS).

The system learns the communication pattern of normal operation within a very short time. The communication is then continuously analyzed down to the level of the frame content, with anomaly detection being controlled by deep packet inspection. Any deviation from the regular communication pattern is reported as an anomaly in real time. Analysis and reporting are completely unreactive and passive and prevent overloading or disruption of the ICS processes.

The network monitoring detects and reports both processes that are relevant for cybersecurity as well as technical error states. Risk assessment, network cards, raw data storage, filters and interface integration support the efficient analysis and defense against attacks and errors. This enables operators and security experts to actively react to risks, prevent disruptions and protect the supply.

Problems that the Industrial Protector solves

- Inventory of the network resources of the control system

- Identification of industrial network devices and their weak points in databases

- Unauthorized access to process control networks and their data

- Monitoring the status of devices in the control system

- Changes in application programs of PLC, IF, instrumentation, HMI; read and change the FW

- Wrong, incomplete packets, communication anomalies

- Deviations in industrial communication from normal behavior (baseline), the appearance of protocols that are atypical for control systems

- Identifying threats from a signature database

- The emergence of new network resources that are not characteristic of process control systems

Rhebo Industrial Protector continuously analyzes the communication in the ICS and evaluates it for anomalies. Both security-related incidents and technical error states are reliably recorded, evaluated and reported in real time - regardless of whether they were previously known or not yet identified.

Features

Benefits of Rhebo Industrial Protector:

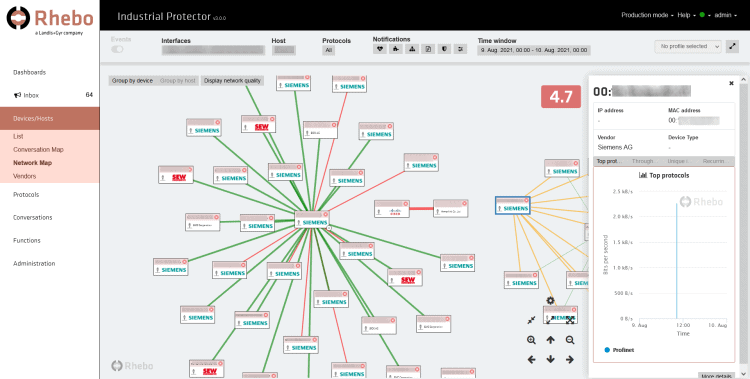

Device visualization

Continuous visualization of all devices, connections and communication flows in the industrial control system as well as the associated properties.

Reports of anomalies

Reporting on all security-relevant and technical anomalies in real time, with a distinction between the first incident and recurring events.

Risk assessment

Instant risk assessment based on the specifications of any anomaly as a security incident or network quality incident.

Detailed analysis

Detailed forensic analysis and evaluation of patches by saving all incident details, including a copy of the raw data in the form of PCAP.

Easy integration

Easy integration of network visibility options into existing server systems via universal interfaces and automated transmission rules.