DELMIA

Solution for technological preparation of production in a single virtual environment

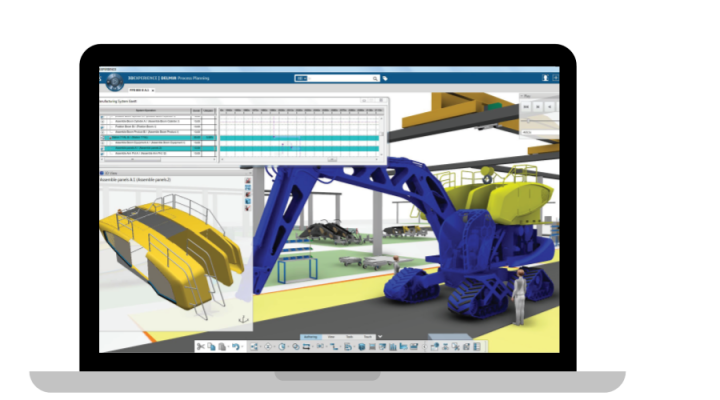

DELMIA helps industries and services to Collaborate, Model, Optimize, and Perform their operations.

DELMIA, powered by the 3DEXPERIENCE platform, helps industries and service providers connect the virtual and real worlds of value networks to collaborate, model, optimize and perform.

Operational excellence requires harmony across the value network. DELMIA provides solutions to leverage the virtual world of modeling and simulation with the real world of operations to provide a complete solution to value network stakeholders: From suppliers, to manufacturers, to logistics and transportation providers, to service operators and workforces.

DELMIA – it is a set of solutions for technological preparation of production in a single virtual environment using tools:

- Planning, modeling, verification of production processes.

- Multi-criteria process optimization.

- 3D work environment design.

- Simulations of manual operations, personnel actions, including ergonomic analysis.

- Planning lead times.

- Designing product quality control processes.

- Modeling production flows and enterprise logistics.

- Modeling, testing and optimization of maintenance and repair processes.

- Generation of technological documentation.

Based on the 3DEXPERIENCE platform, DELMIA helps global enterprises rethink their planning, management and optimization practices.

Features

DELMIA helps manufacturers create digital models for the virtual simulation of products, processes and factory operations.

ADDITIVE PRODUCTION

planning, modeling and programming of additive manufacturing processes

ERGONOMICS

compliance and build verification across platforms

LEAN PRODUCTION

implementation of lean manufacturing practices in production operations in workshops

MACHINING

determination of operating modes of programmable CNC machines

MANAGEMENT OF PRODUCTION OPERATIONS

transformation by manufacturers of global manufacturing operations

ORGANIZATION OF THE PRODUCTION PROCESS

creation and optimization of custom-assembled production systems

ROBOTICS

assessment of device availability, analysis of protection functions and autonomous training of robots

FACTORY IN A VIRTUAL ENVIRONMENT

creating and modeling your factory’s digital 3D twin